Design for excellence (DfX) is a systematic and proactive approach to design that uses the knowledge and experience of experts in other parts of the product development process (test, manufacturing, operations, support, etc.) to ensure the final product can be realized at reasonably low life cycle cost while still meeting reliability, quality, durability, and customer expectation targets.

DfX adopts a holistic approach focused on all aspects of a product from concept generation to final delivery. It provides best practices and design guidelines to ensure the design and manufacturing methods are right from the beginning and throughout the process.

Getting product design right the first time is far less expensive than finding failure later in product development – or by the customer. By assessing issues beyond the base functionality of the product early in the design phase, practitioners of a robust DfX approach achieve significant reductions in defects, scrap, rework, retest, and increases in product yield.

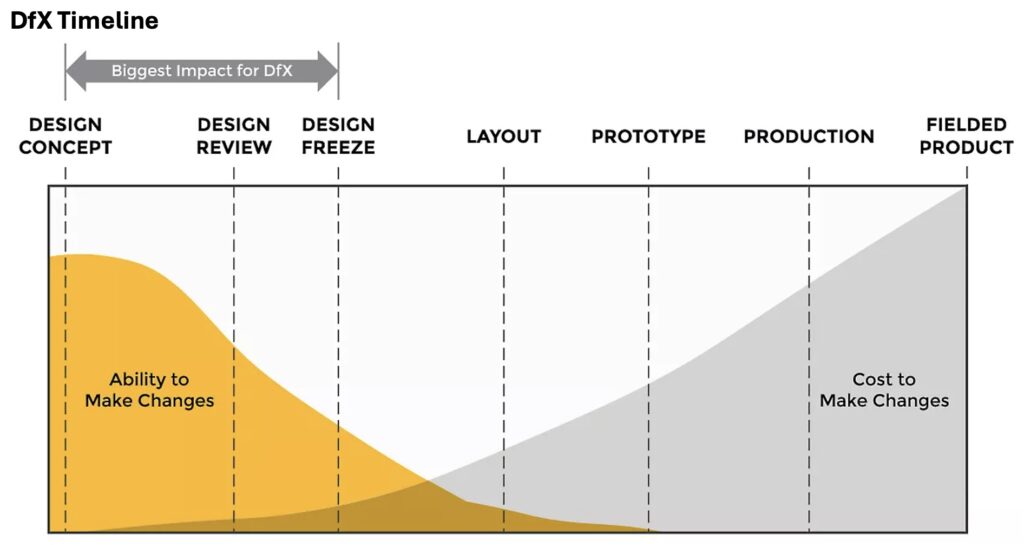

DfX Timeline

Implementing DfX early in the design phase ensures changes can be made quickly before prototype, saving time and costs.

Benefits of DfX

Product differentiation: As technologies reach maturity, there are fewer opportunities to set products apart from the competition through traditional metrics like price and performance. DfX approaches allow companies to keep production and support costs low while achieving impressive reliability and durability that delights their customers.

Reliability assurance: Advancing technologies with new requirements and material make ensuring reliability increasingly difficult. Implementing a DfX approach that includes well-thought-out design for reliability (DfR), design for the environment where customers are using it (DfE), and design for test (DfT) programs significantly lowers the cost of ensuring reliability and reduces the risk of unexpected failures in test or in the field.

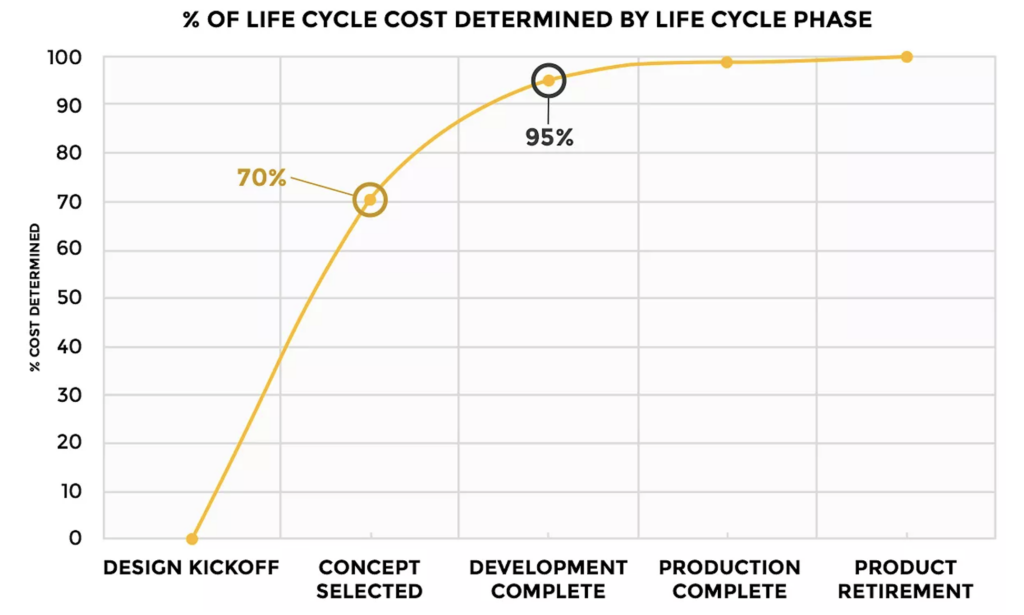

Cost control: Although it varies by product, typically about 70% of a new product introduction project’s cost is determined by the design concept selected. By the time the design process is complete, up to 95% of product life cycle cost is locked in. Design changes after that point are costly and have negative impacts on preproduction program cost and product release timelines.

By using a DfX approach, companies can apply expertise and lessons learned from manufacturing, assembly, testing, packaging, maintenance and repair, actual use environments, and other areas unrelated to design to minimize design, manufacturing, and support costs.

Seventy percent of a new product introduction (NPI) is determined by the design concept selected. By the time the design process is complete, 95% of product development costs are locked in.

Accelerating time to market: Especially in highly competitive markets, getting to market quickly with a product customers want and need is critical to starting ahead of the competition and capturing market share. Getting to market quickly and being recognized as offering one of the best products on the market can be a difficult balance that is made easier through an effective DfX strategy.

Redesign, test failures, and assembly and manufacturing problems all rob valuable time from the new product introduction schedule. DfX approaches bring a concurrent engineering philosophy to design that considers the needs of every product development stage to create a design that will flow through prerelease phases with minimal design-related roadblocks.

—

What is Design for Excellence (DfX)?. Ansys Blog. June 21, 2023. https://www.ansys.com/blog/what-is-dfx

Palmer, Nigel. Design for Excellence (DfX) to Improve Product Cost, Quality, and Time to Market. TT Electronics. 2022.

Sharp, Neil. What is Design for X (DfX) in manufacturing? Escatec. July 7, 2022. https://www.escatec.com/blog/what-is-design-for-x-in-manufacturing

Velling, Andreas. Design for X (DFX) Methods. Fractory. June 17, 2021. https://fractory.com/design-for-x-dfx/

Van Tyne, Sean. Easy to Use 2.0: User Experience in Agile Development for Enterprise Software. Crystal Point Media. 2017

Bean, Jeofrey, Van Tyne, Sean. The Customer Experience Revolution: How Companies Like Apple, Amazon, and Starbucks Have Changed Business Forever Paperback. Brigantine Media. 2011